Outdoor scene

PRODUCTS

12 1/4 inches matrix body pdc bits with 16mm cutters and 5 blades for soft to medium hard formations

Category:

Matrix Body PDC Bits

Product details

PDC matrix body bit is a highly efficient drilling tool widely used in oil, gas, and geothermal well drilling. Its unique design and material combination enable it to perform exceptionally well under various geological conditions, making it suitable for rapid drilling operations in various formations. The 12 1/4 inch, five-blade, 16mm main cutting tooth PDC matrix body bit is one of the efficient, economical, and widely applicable drilling tools currently available on the market.

Bits Specification

| Bit size (in) | 12 1/4" |

|---|---|

| Bit size (mm) | 311.1 |

| Number of blade | 5 |

| Primary cutter size(mm) | 16 |

| Nozzle qty | 8 |

| Gauge length | 2"-3.5" |

| Connection | 6-5/8" API REG |

| Recommended RPM (r/min) | 60-250 |

| Recommended WOB (KN) | 20-110 |

| Recommended flow rate(lps) | 40-55 |

| Net / Gross weight (kg) | *(Based on actual products) |

| Package dimension (mm) | 700×360×360 |

| Applicable Formations | Suitable for soft to medium hard formations. |

| Structural Features | ◆ Made of high-quality tungsten carbide material sintered, with good erosion resistance ◆ Reasonably configured with high-quality PDC composite sheets to increase tooth density, improve drill bit attack and abrasion resistance ◆ Hydraulic structure optimization, wellbore flow field design, conducive to rock debris migration and mud inclusion prevention |

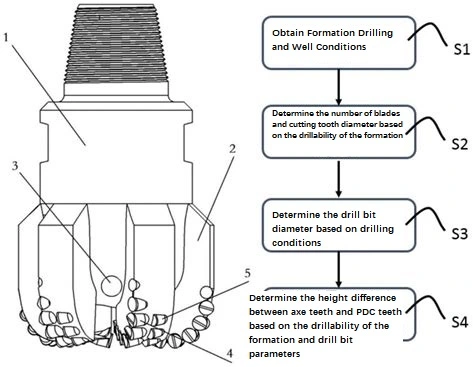

Ruishi Bits Model Description

For details, please refer to the official website of Hebei Ruishi Bits Manufacturing Co., Ltd:

https://www.ruishibit.com/

M | 16 | 5 |

| J1DRT |

Bit Type S: PDC steel body bit M: PDC matrix body bit | Cutter Size | Number of Wings | Suitable Formation Hardness | Characteristic Code |

The Characteristics of PDC Matrix Body Bits

PDC matrix body bits are drilling tools widely used in oil and gas wells, coal mines, and geological exploration. Their high hardness, high strength, long life, and excellent rock-breaking efficiency make them important tools in the drilling field. Their material and structural design allows them to perform exceptionally well in soft to medium-hard formations, while also possessing good erosion resistance and wear resistance. They are suitable for drilling operations under various complex formation conditions. Their comprehensive characteristics are mainly reflected in the following aspects:

Material and Structural Characteristics:

The matrix part of the PDC matrix body bit is usually made using a tungsten carbide powder metallurgy sintering process, which has high hardness, high strength, and good wear resistance, while also having excellent impact resistance. High-entropy alloys or tungsten carbide powder are often added to the matrix material to form a uniformly distributed eutectic structure to improve the overall performance of the matrix. In addition, the PDC cutters welding strength of the matrix body bit is high, usually exceeding 35 kN/mm², effectively withstanding various stresses during the drilling process.

Applicable Formation Range:

PDC matrix body bits are suitable for soft to medium-hard formations, and perform particularly well in medium-hard to hard formations. Their design allows for rapid drilling under different formation conditions, especially suitable for long-distance main hole drilling. In addition, matrix body bits can also adapt to some hard and brittle interbedded formations.

Rock Breaking Efficiency and Cutting Performance:

PDC matrix body bits achieve rock shearing and breaking through polycrystalline diamond composite cutters (PDC), with high rock-breaking efficiency. Their cutting tooth design optimizes tooth shape, rake angle, and tooth density, improving mechanical drilling speed and drilling efficiency. In addition, the matrix body bit has various PDC cutters combinations, and the appropriate cutting tooth type can be selected according to the formation characteristics, such as scraper type, single tooth type, and combination type.

Service Life and Maintenance:

PDC matrix body bits have a long service life, typically reaching hundreds or even thousands of meters. Their manufacturing process is simple, the production cycle is short, and worn parts are easy to replace after repair, thus extending the service life. In practical applications, matrix body bits exhibit good erosion resistance and wear resistance, and maintain a long life even under high flow rate conditions.

Hydraulic Design and Cleaning Capacity:

PDC matrix body bits use a hydraulically balanced design, equipped with replaceable threaded nozzles, which can form an ideal bottom hole flow field, fully cleaning and cooling the cutting teeth. This design not only improves the service life of the cutting teeth, but also enhances drilling efficiency.

Manufacturing Process and Cost Effectiveness:

The manufacturing process of PDC matrix body bits includes mold design, matrix formulation, powder molding, and sintering. The manufacturing cost is relatively high, but the performance is superior, especially in complex formations, outperforming steel bits. In addition, the production cycle of matrix body bits is short, suitable for mass production.

Frequently Asked Questions

Q: What are the advantages of your company?

A: Our company integrates R&D and manufacturing. We are a bit manufacturer with over 30 years of experience in the industry, providing customers with efficient one-stop services including design and development, customized suggestions, manufacturing, direct sales, and after-sales support.

Q: How can I find the bit model I need on the website?

A: You can search for the product you need in the "Product" on the website based on information such as "bit size," "main cutting tooth specifications," "number of blades", etc.

Q: What if I can't find the model I need? What if I don't know how to choose the right model? How to customize products?

A: Click here Contact Us or Message and let us know your needs. We will contact you shortly and provide professional advice in the following areas.

| Bit Type | 2 "-26" full size PDC bit (steel body bit / matrix body bit), tricone bit, core bit, hybrid bit, other drilling tools, etc |

|---|---|

| Bit Parameters | PDC bits (blade number, cutting tooth specifications, composite cutters type, connection), tricone bit (tooth type (TCI/milled tooth), sealing form…) |

| Drilling Information | Logging information, well depth and type (oil well, natural gas well, geothermal well, water well...) |

| Rock Type | Limestone, dolomite, sandstone, clay rock, shale, etc Rock hardness level 1-7, from soft to hard, or "extremely soft, medium soft, soft, medium hard, hard, extremely hard" |

| Geographic Location | Domestic and foreign, specific sections, and transportation weight |

| Other technical questions | - |

Q: How long does it take for customized products to arrive?

A: Sample models are generally completed in 3 days, and shipments during peak season take 15 days. Transportation methods include land, sea, air, or other methods.

Q: How can I resolve technical questions? How can I get a quote?

A: Please contact rszwt2023@ruishibit.com or WeChat zom2077. We will arrange a professional to address your technical questions and provide a quote as soon as possible.

Q: What accessories are included with your drill bits?

A: There will be relevant instructions in the packaging.

Q: What other related products or services does your company offer?

A:Our company not only produces various types of PDC drill bits and three cone drill bits, but also manufactures hydraulic oscillators, roller cone hole openers, engineering palm films, rotary drilling tools, downhole motor and diamond wire drawing die blanks. If you have any other industry related questions, we will do our best to answer them for you.

...

Company Qualifications

Hebei Ruishi Bits Manufacturing Co., Ltd. established in 1990 is a long-term first tier supplier of CNPC, Sinopec, and CNOOC.

We have a group of technical experts who have been engaged in drill bit design for more than 30 years, advanced five axis machining centers, and a large number of CNC machine tools, which can produce 2 "-26" full model PDC drill bits, various types of tricone drill bits, core drill bits, composite drill bits, hydraulic oscillators, roller cone hole openers, engineering palm films, rotary drilling tools, downhole motor and diamond wire drawing die blanks, which can be customized according to customer’ needs.

We strictly adhere to the ISO9001 quality management system, ISO14001 environmental management system, and ISO45001 occupational health and safety management system in our enterprise operations, and strictly implement the API-7-1 quality management standard in the production process. For details, please go to the Honors page.

The company is equipped with a dedicated fleet, located in a location with developed transportation, close to the Beijing Kowloon Railway and the Daguang Expressway, and the Jinbao South Line crosses east-west.

The sample molding is completed in 3 days, and the peak season shipment can arrive on the 15th. Our drill bits have undergone 30 years of rigorous research and development, and have received a high praise rate of over 99% from customers.

Ruishi's products are widely used in major oil fields such as Tarim, Tuha, Changqing, Dagang, Sichuan, Central China, Jidong, and North China, and we have established long-term strategic partnerships with them. The stability of our excellent product quality and timely and thoughtful service has been highly recognized by our customers. Our products have been widely exported to countries and regions such as North America, the Middle East, and Russia.

Just for you

4 5/8 inches steel body pdc bits with 13mm cutters and 5 blades for soft to medium hard formations

View details →4 5/8 inches steel body pdc bits with 13mm cutters and 4 blades for medium soft formations

View details →5 1/2 inches steel body pdc bits with 16mm cutters and 5 blades for soft to medium hard formations

View details →6 inches steel body pdc bits with 13mm cutters and 4 blades for soft to medium hard formations

View details →6 inches steel body pdc bits with 13mm cutters and 5 blades for soft to medium hard formations

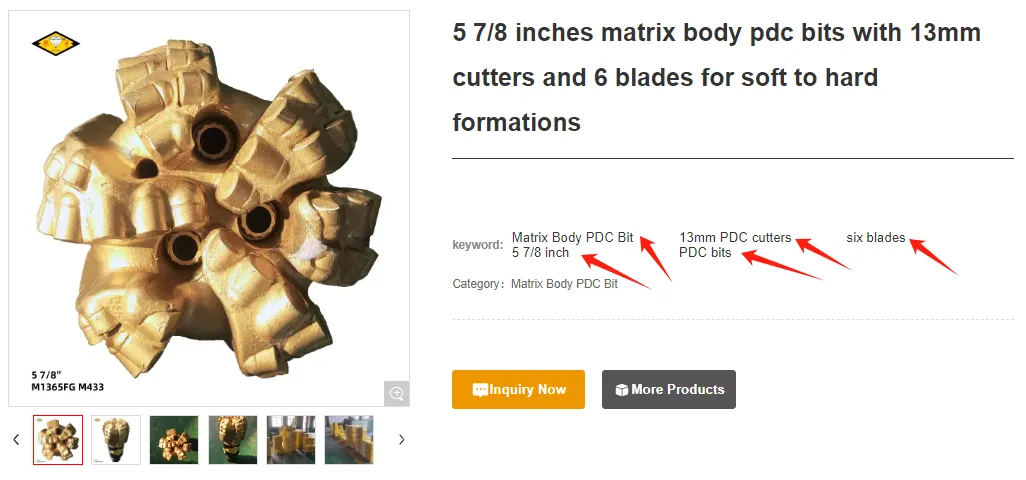

View details →5 7/8 inches matrix body pdc bits with 13mm cutters and 6 blades for soft to hard formations

View details →Get Quotation

We will contact you within one working day. Please pay attention to your email.

To: Hebei Ruishi Bits Manufacturing Co.,Ltd